Metallic Biomaterials Research Networks

The Istitute of Metallic Biomaterials is involved in various research networks. The scope ranges from the coordination of large EU consortia, a Helmholtz Virtual Institute and a cooperation within the framework of the Röntgen-Ångström Cluster (RÅC) to the participation as partner or coordinator of BMBF and DFG collaborative projects and the Graduate School M4B - Materials for Brain.

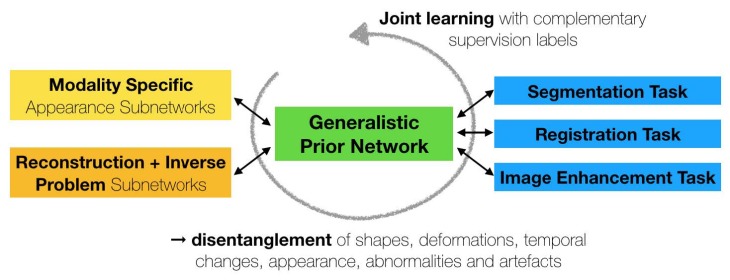

BMBF computational life science - MDLMA (2020 - 2023)

MDLMA network model

MDLMA - Multi-task Deep Learning for Large-scale Multimodal Biomedical Image Analysis

In order to be able to efficiently process and analyze the ever-growing number of biomedical data from a wide variety of sources or imaging modalities, the project develops generic deep learning (DL) methods.

The methods and software tools developed in the project are used to study and develop biodegradable magnesium-based implant materials.

Under the leadership of Prof. R. Willumeit-Römer, the project involves the Hereon, two institutes of the University of Lübeck, DESY and the company Syntellix AG.

HGF Incubator - Uncertainty Quantification (2019 - 2023)

Uncertainty Quantification - From Data To Reliable Knowledge

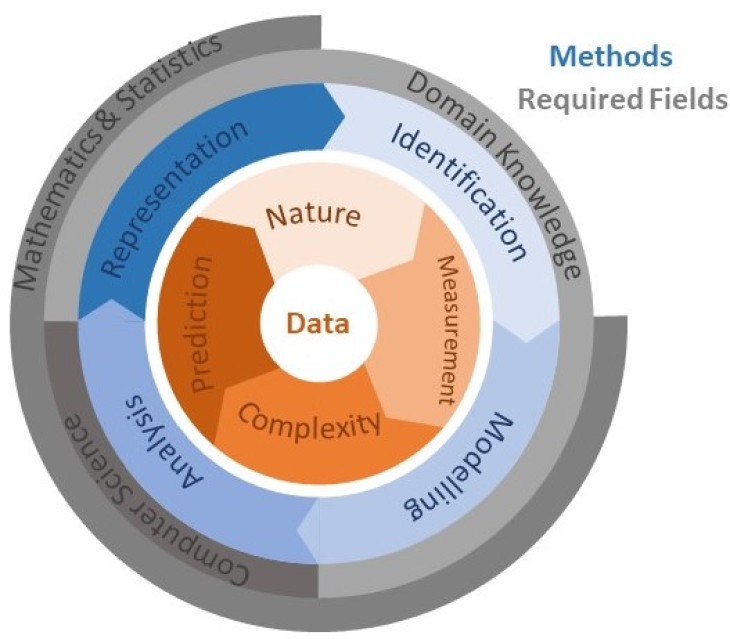

Science has entered an era in which an avalanche of data becomes available, and Helmholtz researchers are at the forefront of experimental and simulation sciences contributing to this development. One of the biggest challenges nowadays is to use such data to solve the major questions asked by society, science and economy.

Both data and methods are subject to uncertainty, which is often considered as unavoidable burden in real-world applications. Using appropriate analytical methods, however, uncertainty can be turned into a valuable source of information.

The aim of this project is to provide a common framework for knowledge transfer in the area of uncertainty quantification (UQ). It connects applied researchers with those from mathematics, statistics and computer science. In addition, we build collaborations between research centers and application areas in order to fully exploit the decentralized expertise of the Helmholtz Association.

The project involves a total of seven Helmholtz centers working together. The task of our group at Hereon is to link the computer modeling of magnesium alloy corrosion with the many available data to quantify the predictive power of the model based on the amount and quality of the data used as input and validation.

Graduate School M4B - Materials for brain (2017 - 2023)

Materials for Brain: Thin film functional materials for minimally invasive therapy of brain diseases

Cooperation between the Christian-Albrechts-University of Kiel (CAU), the University Clinic of Schleswig-Holstein (UKSH) and the Helmholtz Center Hereon (Hereon).

Within the framework of the Graduate School, minimally invasive treatment strategies for diseases of the brain based on novel thin-film material compounds are to be explored in a complexity and functionality that goes far beyond previous approaches. The realisation of such treatment strategies in clinical medicine will be a milestone in the therapy of these diseases.

The development of such cutting-edge localized therapies and suitable functional materials requires substantial collaboration between materials science and medicine, as well as new approaches to solutions and creative openness to the view of the respective other subject.

EU MSCA ETN MgSafe (2018 - 2022)

Promoting patient safety by a novel combination of imaging technologies for biodegradable magnesium implants

As part of the Marie Skłodowska Curie Action (MSCA) the European Training Network MgSafe, 15 young researchers investigate biodegradable magnesium implants. The project is coordinated by the Helmholtz Zentrum Hereon (Hereon); it brings together eight universities and research institutions as well as four technology companies from eight European countries. The European Union (EU) provides a funding programme of about four million euros.

For their research, the young scientists use various imaging methods, which will enable them to most precisely monitor the behaviour of magnesium implants during the process of bio-compatible degradation.The obtained multimodal imaging data are combined with molecular biological / biochemical analysis, thereby increasing the information about physiological changes. All relevant biological and chemical in vivo and ex vivo data are merged by computational 3D methods, simulations and machine learning approaches.

Prof. Dr. Regine Willumeit-Römer, coordinator of the project and Head of the Institute of Metallic Biomaterials at the Helmholtz Zentrum in Geesthacht, explains: "Biomedical imaging is fundamental to both diagnosis and therapy, because we need to monitor the behaviour of the degrading implant materials. There is still need for improvement as far as the new class of biodegradable magnesium-based implants is concerned. In the MgSafe project, we will establish new techniques while educating 15 PhD students interdisciplinary in both imaging and implant technologies."

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 811226

How MgSafe will improve patient safety and what the project is all about:

MgSafe: X-ray vision in 360°

15 PhD students push the safety of degradable magnesium implants even further - within the EU project MgSafe

DFG - OAMag Therapie (2018 - 2021)

Two researchers (Dr med. vet. Nina Angrisani, Hannover Medical School, and Prof. Dr Regine Willumeit-Römer, Helmholtz-Zentrum Hereon) and their work groups aim to develop an alternative treatment for cartilage lesions using degradable beads made of magnesium and a magnesium-alloy. The research is based on the assumption that magnesium improves the surrounding bone structure. Magnesium (alloy) beads will be implanted into subchondral bone tissue, where they are expected to degrade and thereby positively influence the surrounding tissue.

While magnesium is well-known in the scientific community as implant material, this may be the first attempt to deploy it in the treatment of damaged cartilage. The in vitro and in vivo tests will improve an understanding of magnesium's influence on bone and cartilage. A positive outcome may also significantly improve the treatment of osteoarthritis in the long term.

Based on available material, beads with dimensions of about 0.5 mm have been produced. Degradation properties and biocompatibility are tested in vitro, followed by the employment of a well-known animal model to address the various research questions in and ex vivo, using methods such as µ-computer tomography, protein expression analysis and histological analysis.

Helmholtz-RSF Joint Research Group (2018-2021)

Materials based on magnesium alloys for bioresorbable implants with anti-tumour activity

A Russian-German research collaboration in the fields of resorbable metallic implants as anti-tumour agents. Our Russian project partners are the National University of Science and Technology MISIS, NUST MISIS and the N.N. Blokhin Russian Cancer Research Center.

The project addressed a core problem in modern oncology: the application of local chemotherapy that aims to achieve an efficient concentration of anti-tumor agents in the intra- or peritumoral regions. The chosen approach based on degradable Mg-based implants is to result in a cytoreduction of unresectable and chemo-resistant tumors, while at the same time reducing the side effects for the patients.

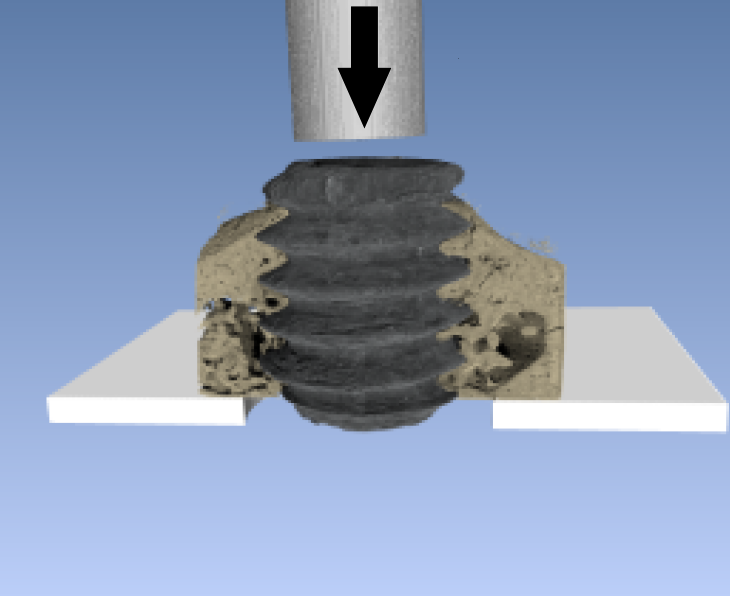

RÅC - SynchroLoad (2016-2020)

SynchroLoad - Failure in biodegradable metal implants

A Swedish-German research collaboration in the fields of materials science and structural biology (Röntgen-Ångström-Cluster).

The aim of this project was to understand how implant degradation and failure mechanisms work for a biodegradable Mg implant where corrosion processes and (bio)chemistry form a complex network of interactions in the living system. The tissue-to-implant interface was characterized biomechanically, morphologically, biologically and chemically. Finally, a comparison of the bone structure around different implant materials was performed.

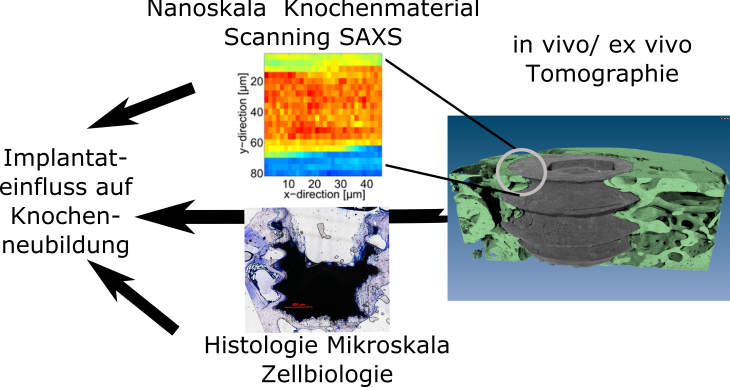

MgBone (2016 -2019)

MgBone - Multimodal imaging for structural analysis of bone modeling induced by degraded magnesium implants

Cooperation in the context of the funding sheme research on condensed matter on large devices. There are three partners: The Molecular Imaging North Competence Ceter (MOIN CC) in Kiel, the Helmholtz Center Geesthacht (HZG) and the Department of Prosthodontics of the University of Malmö (MAH).

The aim of the project was to jointly create a measurement and evaluation environment and competence network with the help of which the biomechanical, biomedical, biochemical and physical suitability of innovative implants can be evaluated.

One focus of HZG was the further development of established synchrotron technologies with regard to new sample environments. Drafts and concepts for a push-out cell were developed with which the mechanical stresses in bone and implant can be characterized in situ using X-ray scattering techniques.

Another task of HZG was to examine Mg implants in bone using various synchrotron techniques and merge the results (multimodal evaluation chain). The samples were first characterized using high-resolution synchrotron tomography (SRμCT) in order to study the morphology of the implant, the bone and the degradation products. Investigations with high-resolution small and wide angle scattering (SAXS and XRD) were then carried out in order to assess the bone ultrastructure at the bone-implant interface .

It could be shown that hydroxyapatite crystals in the newly formed bone are much more disordered than in areas that are more distant.

Data obtained in the project enable conclusions about the type of new bone formation at the implant interface and thus contribute to the development of future implants. The aim is to develop implant material specifically with regard to its interaction with bone tissue. This can only succeed if we understand the mutual influence of bone healing and magnesium corrosion.

Helmholtz Virtual Institute MetBioMat (2012 - 2017)

VI MetBioMat - In vivo studies of biodegradable magnesium based implant materials

In collaboration with the university hospitals of Hamburg, Hannover and Graz as well as further partners, the Helmholtz-Zentrum Geesthacht had established a Virtual Institute, whose focus was on degradable magnesium implants. One aim of the research association coordinated from Geesthacht was to develop first prototypes of orthopaedic implants.

The Virtual Institute MetBioMat was one of the Helmholtz Virtual Institutes and lead by Prof. Regine Willumeit-Römer of the Helmholtz-Zentrum Geesthacht. By establishing new research partnerships, Helmholtz Virtual Institutes provided a distinct benefit in preparing the way for larger strategic research projects. With this funding the Helmholtz Association wanted to strengthen the position of universities in the German scientific system. A further aim of the funding programme was to generate new collaboration with leading international partner institutions and the industry.

EU-MCA ETN MagnIM (2011 - 2015)

EU-MSCA ETN MagnIM [289163] - Tailored biodegradable magnesium implant materials

Cost reduction and improvement of the quality of life is a major issue in health care. This challenge can be tackled by intelligent biomaterials and smart implants which are resorbed by the body upon remodelling of the tissue: What is possible for polymer materials should also be realized for biodegradable metallic materials. “MagnIM - Tailored biodegradable magnesium implant materials” trained 12 ESRs from 9 countries (3 male, 9 female) to contribute to this demanding aims by the development of new aluminium free magnesium implant materials with tailored properties specific for bone related applications especially in children and for sports medicine.

The project was structured such a way that it covered the complete value-added chain from material development and characterisation over in vitro to finally in vivo studies and application. Central point was the optimisation of material properties of aluminium free biodegradable magnesium alloys. To do so a new class of alloys considering computational tools was developed. The processing of the new alloys was be optimised leading to materials which were produced reliably and thus can be applied in orthopeadics and sports medicine. All materials were characterised as produced and in heat treated conditions to gain knowledge on the full property profile (microstructure, mechanical properties ), corrosion, in vitro and in vivo performance. Especially the latter were needed to bring a new implant into application. But as important was the aspect to bridge the gap between the observations made for Mg degradation in vitro and the fundamentally different results obtained in vivo. Therefore, comprehensive chemical understanding of corrosion were combined with the knowledge about cellular reactions to the new materials in order to create an in vitro test system which allowed for reliable prediction of the in vivo properties of the degradable material. To do so a complete set of parameters obtained from in vivo experiments was implemented in a feedback procedure.