Blending is the Trick: Tailored Pores in Block Copolymer Membranes

A simple trick generates custom-tailored pores. Maryam Radjabian has developed a surprisingly uncomplicated method for obtaining the desired pore size in block copolymer membranes. The results of her research were published in the distinguished international scientific journal Advanced Materials.

![By blending of two block copolymers a mean pore size is formed in the membrane with a linear dependence on the blending ratio. [Figure HZG] By blending of two block copolymers a mean pore size is formed in the membrane with a linear dependence on the blending ratio.](/imperia/md/images/hzg/presse/pressemitteilungen/2015/fittosize__730_0_7c5a443be4d7539b2c1229c8855edada_kombi_englisch_final.jpg)

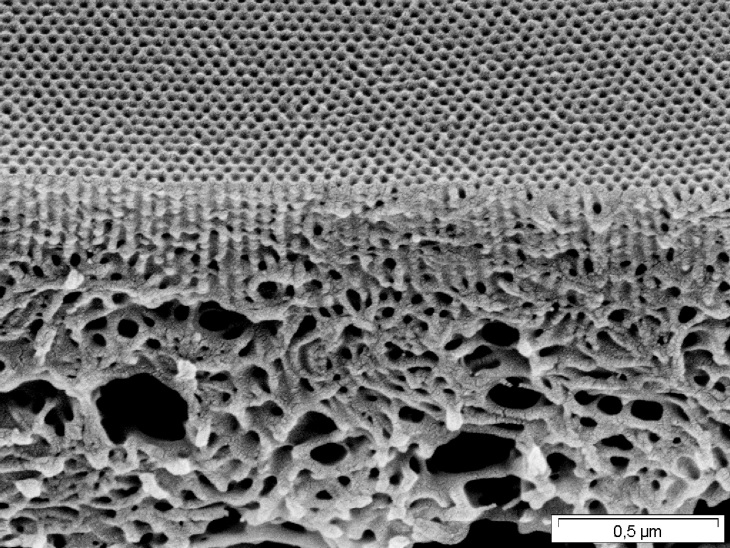

By blending of two block copolymers a mean pore size is formed in the membrane with a linear dependence on the blending ratio. [Figure HZG]

Whether it’s water treatment or virus and protein separation, porous membranes are utilised in many different separation functions. What is particularly fascinating and highly promising is isoporous membrane production from block copolymers. Under suitable conditions, block copolymers can form highly ordered structures, ideally uniform pores, through self-assembly (see “Block Copolymer Information” below).

In order to develop effective membranes for special separation functions, the correct pore size is crucial. This objective presents the greatest challenge: how must the block copolymer be composed in order to obtain the desired pore size? To date, for every newly developed isoporous membrane a special block copolymer was synthesized, which then resulted in the necessary pore size.

In cooperation with the director of Geesthacht’s Institute of Polymer Research, Prof. Volker Abetz, Dr. Maryam Radjabian has now developed a time-saving and surprisingly simple method: by blending of two block copolymers, the pore size can be adjusted via the blending ratio.

The fluid polymer material is thinly applied to a supporting membrane. Photo: HZG/ Christian Schmid

The two block copolymers consist of the same monomers but differ in the number of repetition units in the blocks. A different pore size then arises in the particular membrane cast from each block copolymer.

Dr. Radjabian’s concept of obtaining an average pore size by blending two block copolymers has been corroborated in experiments. This opens up entirely new possibilities for designing new membranes.

The scientist at the Institute of Polymer Research explains, “There is a substantial advantage in not having to synthesize a precisely suitable block copolymer to obtain the desired pore size, but in simply mixing two approximately suitable copolymers together.”

Block Copolymer Information:

Isoporous Membrane: Self-assembly of the macromolecules takes place through rejection reactions (microphase separation) [Pic: HZG]

Block copolymers consist of at least two types of monomers, each covalently linked together as polymer blocks (a group of the same monomers) in the form of a macromolecule. Because the blocks of macromolecules are selected so that they are not mixable (“immiscible”), self-assembly of the macromolecules takes place through rejection reactions (microphase separation). Isoporous Membranes can be produced from a block copolymer solution under defined conditions by utilising the phase inversion principle. The foundations for this research were developed within the HZG-coordinated European Union project SELFMEM (2009-2012).

Contact:

Max-Planck-Str. 1

21502 Geesthacht