H2Free

• ELSYCA (BE)

• AZTERLAN (ES)

• ELHCO (ES)

• MPIE (DE)

Aircraft landing gear structure constructed with UHSS

Abstract: The main objective of the H2Free project is to develop a practical guideline for hydrogen degassing of UHS-steels plated with LHE-Zn-Ni, with the aim of saving production costs and allowing

Zn-Ni to overtake Cd coatings.

Keywords: Hydrogen embrittlement, modelling, hydrogen degassing, hydrogen kinetics, UHSS, Zn-Ni, plating, corrosion, guidelines.

Project motivation: Coated Ultra High Strength Steels (UHSS) are used for constructing aircraft parts, since they offer lightweight and high strength. However, these UHSS parts are highly susceptible to hydrogen embrittlement, which drastically changes their properties and may lead to disastrous accidents. Thus, the degassing stage during the production of these parts plays an important role in reducing the concentration of hydrogen.

The degassing process, the degassing efficiency and the hydrogen intake are dependent on the nature and structure of the coating and base steel. Therefore, a better understanding of the degassing process will aid in developing efficient degassing techniques to be used in the industry and reduce the amount of scrap, which in turn has a positive impact on the environment.

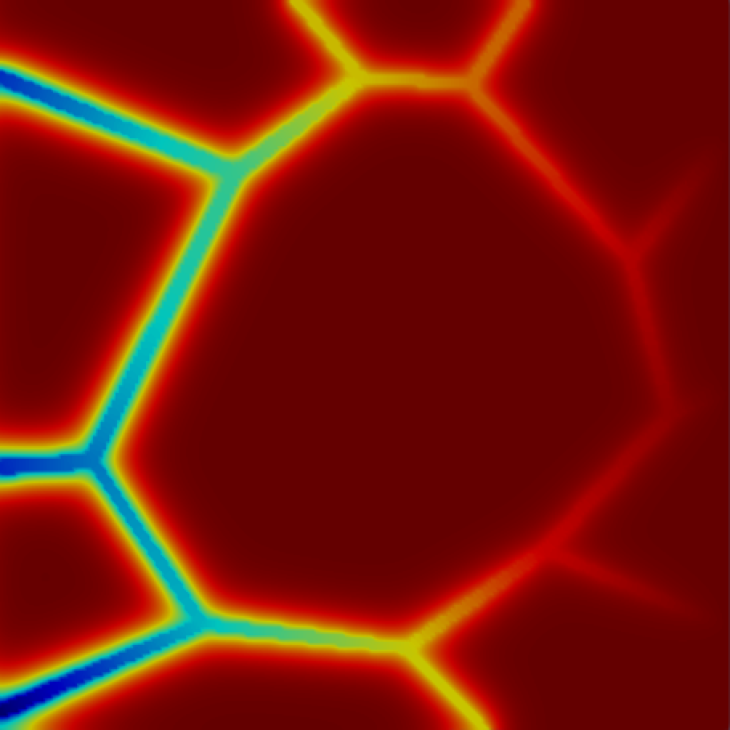

Effusion Of Hydrogen Along The Grain Boundaries

Hereon’s part: At Hereon, we are developing a simulation model that captures the effusion of hydrogen in electrochemically plated UHSS. The model developed at Hereon simulates the effusion of hydrogen in the base steel and in the coating and captures the surface reactions that lead to the escape and intake of hydrogen. The model will support four different UHSS and multiple coating microstructures as well. Calibration of the model will be done in accordance with the experimental data provided by the other partners. Finally, a computationally cheap surrogate model will be developed and employed in commercial plating software.

Project updates:

• Finite element method is chosen as the modeling approach for the development of the model, since a complex partial different equation with many parameters has to be solved over a complicated domain of the microstructure.

• FEniCS, an open source partial differential equation computing library, is the modeling platform used, since it is widely accepted in the scientific community and offers excellent versatility and flexibility needed for the project.

• An initial model has been set up with a microstructure based on data from literature. The model already supports a complex microstructure with multiple grains. The model captures the flow of hydrogen in steel along the grain boundaries and dissipation into the atmosphere.

Contact